Introduction:

The renewable energy industry is experiencing an unprecedented boom. As we collectively strive towards a more sustainable future, the demand for cleaner, more efficient energy sources is growing. At the heart of this growth and innovation is Computer Numerical Control (CNC) machining, a technology that is proving to be indispensable in the renewable energy sector.

The Importance of CNC Machining in the Renewable Energy Industry:

CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process allows for high precision, efficiency, and scalability, making it a crucial component in the renewable energy sector.

CNC machining’s ability to work with a variety of materials, including those that are heat-tolerant and high-strength, makes it particularly valuable in an industry where components often need to withstand extreme conditions. From gears and seals to pumps and valves, CNC machining is behind the production of a wide range of parts and components that keep the renewable energy sector moving forward.

Case Studies of CNC Machining in Renewable Energy:

Solar Energy:

Solar energy is one of the fastest-growing sectors within the renewable energy industry. The production of solar panels involves several complex processes, many of which rely heavily on CNC machining. From cutting and shaping solar panel components to drilling holes for assembly, CNC machines are integral to the production line.

Moreover, the evolution of CNC technology has led to the development of versatile robotic arms and specialized software that simplify the process and optimize space and labor utilization. This has been a game-changer in the solar energy sector, allowing for more efficient and cost-effective production.

Hydro Energy:

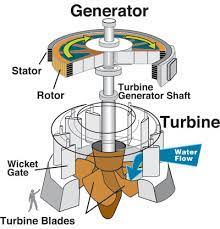

Hydropower is another significant player in the renewable energy industry. The production of hydropower turbines and generators requires high precision and durability, making CNC machining the ideal manufacturing process.

CNC machines are used to create complex parts for hydroelectric turbines, often on a massive scale. For instance, Canyon Hydro in North America uses a 7-axis CNC milling machine capable of fabricating Pelton and Francis hydroelectric turbines up to 16 feet in diameter while weighing 25 tons. This level of precision and scalability is crucial in the hydro energy sector, where even minor imperfections can have significant impacts.

The Future of CNC Machining in Renewable Energy:

As the demand for renewable energy continues to rise, the need for advanced manufacturing techniques like CNC machining will only grow. The industry is expected to continue evolving to meet the dynamic needs of the renewable energy sector, with a focus on improving efficiency, precision, and scalability.

Moreover, as renewable energy technologies become more complex, the role of CNC machining in their production will likely become even more critical. From developing more efficient solar panels to creating more powerful hydroelectric turbines, CNC machining will continue to drive innovation in the renewable energy industry.

Conclusion

CNC machining is not just a part of the renewable energy industry; it’s a driving force. Its ability to provide high precision, efficiency, and scalability makes it an indispensable tool in the production of renewable energy technologies. As we look to the future, the role of CNC machining in renewable energy is only set to grow, driving innovation and helping us move towards a more sustainable future.