Introduction

In the intricate world of modern manufacturing, certain tools are indispensable. They form the backbone of numerous applications, driving the production of a vast array of items we use daily. One such tool is the endmill, a type of milling cutter that has carved its niche in industrial milling applications. This blog post aims to shed light on the crucial role of endmills in modern manufacturing, exploring their fundamental design, diverse applications, and their evolving role in the face of new manufacturing technologies.

Understanding Endmills

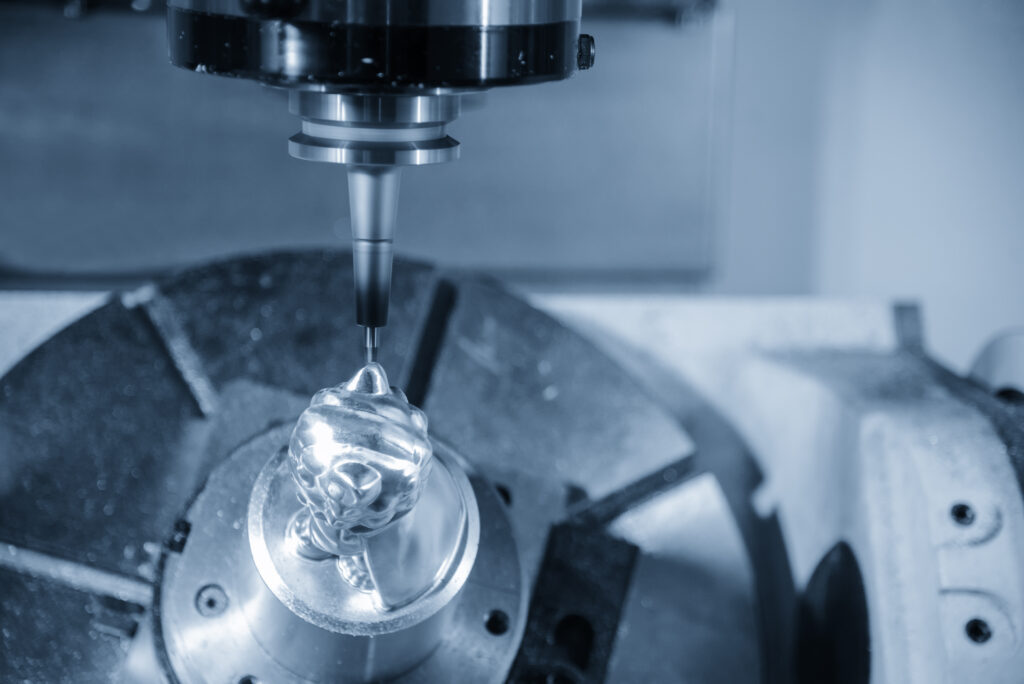

Endmills are unique in their application, geometry, and manufacture, distinguishing them from other tools such as drill bits. They are designed to perform cutting tasks with precision and reliability, making them an essential tool in the manufacturing industry.

Endmills come in various shapes and sizes, each designed for specific applications. They can have different numbers of flutes or cutting edges, and they can be made from different materials, with solid carbide being a popular choice for its hardness and heat resistance. The geometry of an endmill, including the design of its flutes and the angle of its cutting edge, can significantly affect its cutting performance and the finish of the machined part.

Applications of Endmills in Modern Manufacturing

Endmills are used in a wide range of machining operations. These include milling, where they cut a path through material; holemaking, where they drill or bore holes; and contouring, where they shape the material to a specific profile. They are also used in operations such as drilling, reaming, and profiling, demonstrating their versatility.

The role of endmills extends to the production of many items we encounter daily. From the cars we drive to the airplanes that transport us across the globe, endmills play a part in their creation. They are used in industries ranging from automotive and aerospace to electronics and medical device manufacturing, underscoring their importance in modern manufacturing.

The Manufacturing Process of Endmills

The manufacturing process of endmills is a meticulous one. It involves several stages, from the initial design and selection of materials to the precise machining of the tool’s geometry. One of the most critical aspects of this process is the creation of the cutting edge. The quality of the cutting edge, which results from careful process control during manufacturing, is a decisive factor for the performance of milling tools.

At Kwan Fung Precision Tool and Coating, we ensure that our endmills are manufactured to the highest standards. We understand the importance of the cutting edge quality and invest significant time and resources into achieving it. This commitment to quality ensures that our endmills provide reliable and efficient performance in all applications.

Endmills and Additive Manufacturing

The role of endmills is not static; it evolves in response to market demand and advancements in technology. One area where this is evident is in additive manufacturing, a technology that builds parts layer by layer from a digital model. Companies like OSG Corporation have launched new endmill series engineered specifically for metal additive manufacturing, highlighting the adaptability of these tools.

At Kwan Fung, we are committed to staying at the forefront of these advancements. We continually innovate to meet the needs of modern manufacturing, ensuring that our tools are suited to both traditional and emerging applications.

Conclusion

Endmills, with their diverse applications and evolving roles, are truly the workhorses of modern manufacturing. As we look to the future, their importance is set to increase, with advancements in technology opening up new possibilities for their use. At Kwan Fung Precision Tool and Coating, we look forward to being a part of this exciting journey, providing high-quality tools that help shape the world around us.

About Kwan Fung Precision Tool and Coating

Kwan Fung Precision Tool and Coating, based in Hong Kong with our factory in China, is a leading manufacturer of solid carbide cutting tools. We are committed to delivering quality, precision, and innovation, helping to drive the success of modern manufacturing. Our endmills, manufactured with meticulous attention to detail, are a testament to this commitment. They embody our dedication to quality and our drive to meet the evolving needs of the manufacturing industry.

As we continue to innovate and adapt, we remain focused on our customers. We understand that our success is tied to the success of the manufacturers who use our tools, and we strive to provide them with the best possible products. Whether it’s through the development of new endmill designs for emerging technologies or through the continual refinement of our existing products, our goal is to help our customers achieve their manufacturing objectives.

In the ever-changing landscape of modern manufacturing, we believe that tools like endmills will continue to play a pivotal role. They are not just tools; they are enablers, facilitating the creation of products that drive our economy and improve our lives. As we look to the future, we are excited about the possibilities. New materials, new technologies, and new manufacturing techniques will undoubtedly present new challenges, but with these challenges come opportunities for innovation and growth.

At Kwan Fung Precision Tool and Coating, we are ready to seize these opportunities. We are committed to staying at the forefront of tool manufacturing, continually investing in research and development to ensure our tools meet the demands of modern manufacturing. We are excited about the future of manufacturing, and we are proud to be a part of it.

In conclusion, endmills are more than just a tool; they are a testament to human ingenuity and the power of manufacturing. They remind us that even the smallest tools can have a significant impact, shaping not just materials, but the world around us. As we continue to explore the role of endmills in modern manufacturing, we look forward to discovering new applications, new possibilities, and new ways to drive the future of manufacturing.