In the world of manufacturing, efficiency and cost-effectiveness reign supreme. Every dollar saved and every minute shaved off production time translates to a significant competitive advantage. This is especially true for CNC machining, a process known for its precision and versatility, but also for its potentially high costs. Enter Elon Musk, the visionary entrepreneur behind Tesla and SpaceX, with his pragmatic approach to cost reduction embodied in the “Idiot Index.” This deceptively simple metric holds the key to unlocking hidden savings and optimizing CNC machining processes for maximum efficiency.

Demystifying the “Idiot Index”: A Simple Ratio with Profound Implications

The “Idiot Index,” far from being an insult, is a powerful tool for introspection and process improvement. It’s calculated using a straightforward formula:

Idiot Index = Cost of Finished Component / Cost of Raw Material

This ratio shines a light on the value added (or potentially wasted) during the manufacturing process. A high “Idiot Index” indicates that a significant portion of the component’s cost is attributed to processing, design complexity, or inefficiencies rather than the raw material itself. This presents a clear opportunity for cost reduction and optimization.

Why the “Idiot Index” is a Game-Changer for CNC Machining

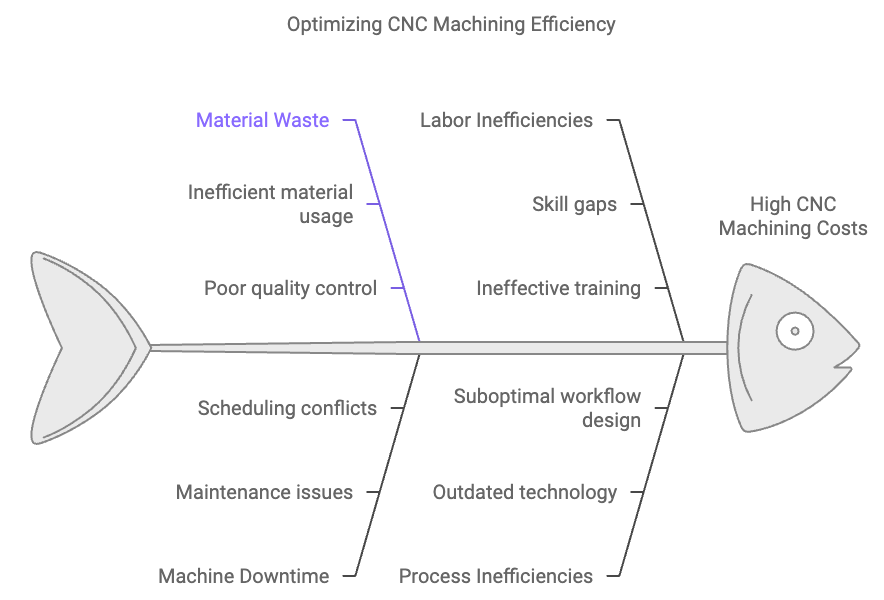

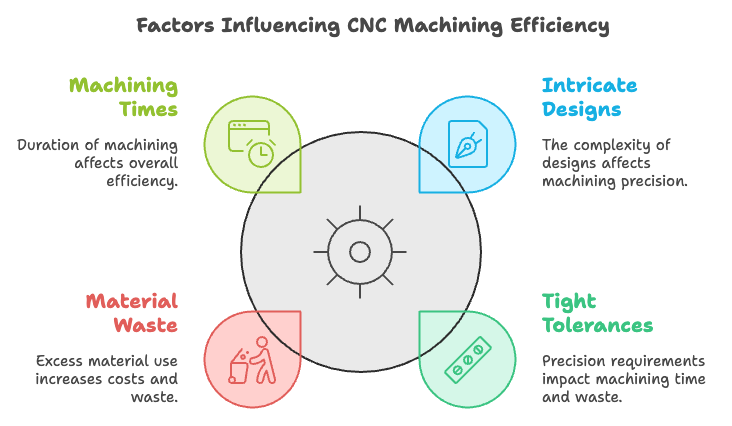

CNC machining, with its ability to produce intricate designs and meet tight tolerances, is often associated with high material waste and lengthy machining times. These factors contribute directly to a higher “Idiot Index.” By embracing this metric, CNC machinists can gain valuable insights into their operations and identify areas ripe for improvement.

Here’s why the “Idiot Index” is particularly relevant for CNC machining:

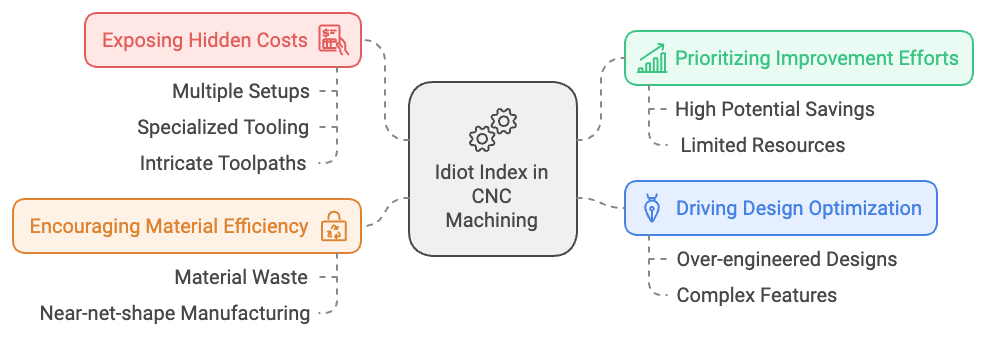

- Exposing Hidden Costs: Complex CNC machining processes often involve multiple setups, specialized tooling, and intricate toolpaths. These factors, while necessary for achieving the desired precision, can drive up costs. The “Idiot Index” helps quantify these hidden costs, making them visible and manageable.

- Prioritizing Improvement Efforts: With limited resources and time, it’s crucial to focus on areas where the greatest impact can be made. The “Idiot Index” acts as a roadmap, highlighting components and processes with the highest potential for cost savings.

- Driving Design Optimization: A high “Idiot Index” often points to over-engineered designs. By analyzing the index, engineers can identify features that add complexity and cost without significant functional benefit, leading to more streamlined and efficient designs.

- Encouraging Material Efficiency: CNC machining often involves removing a significant amount of material to achieve the final shape, leading to waste. The “Idiot Index” encourages machinists to optimize material usage, explore near-net-shape manufacturing techniques, and minimize scrap.

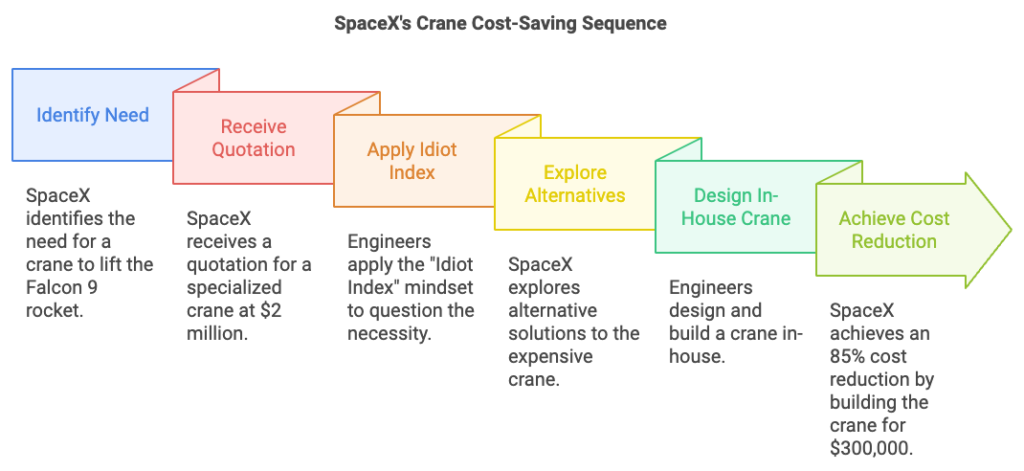

Learning from the Best: SpaceX and the $2 Million Crane

SpaceX, Elon Musk’s space exploration venture, is a prime example of a company that lives and breathes the “Idiot Index” philosophy. Their relentless pursuit of cost-effectiveness is legendary, and the story of the $2 million crane perfectly illustrates their approach.

When faced with the exorbitant price tag of a specialized crane for lifting their Falcon 9 rocket, SpaceX engineers balked. Instead of accepting the quoted price, they applied the “Idiot Index” mindset. They questioned the necessity of such a complex and expensive piece of equipment and explored alternative solutions.

The result? SpaceX designed and built their own crane in-house for a fraction of the cost – a mere $300,000. This 85% cost reduction wasn’t achieved through cutting corners but through clever engineering, efficient design, and a willingness to challenge the status quo.

This anecdote highlights the power of the “Idiot Index” as a catalyst for innovation. It encourages a shift in perspective, prompting engineers and machinists to question assumptions and explore unconventional solutions that can lead to significant cost savings and improved efficiency.

A Practical Guide to Implementing the “Idiot Index” in Your CNC Machining Operations

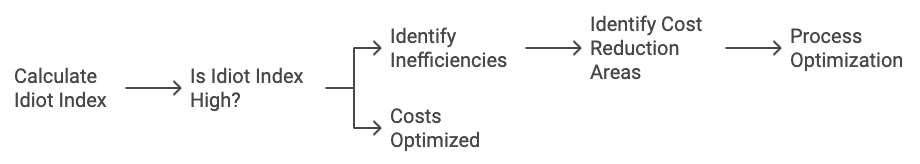

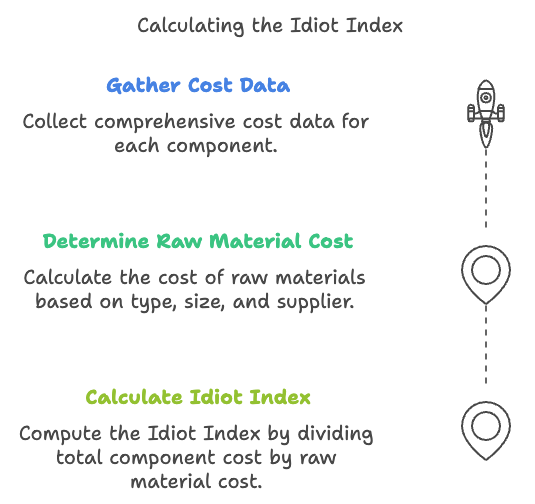

The beauty of the “Idiot Index” lies in its simplicity and practicality. Here’s a step-by-step guide to incorporating this powerful metric into your CNC machining workflow:

1. Data Collection and Calculation:

- Gather Cost Data: For each machined component, determine the total cost, including raw material, machining time, tooling, setup, and any additional processing.

- Determine Raw Material Cost: Calculate the cost of the raw material used for each component based on its type, size, and supplier pricing.

- Calculate the “Idiot Index”: Divide the total component cost by the raw material cost to obtain the “Idiot Index” for each part.

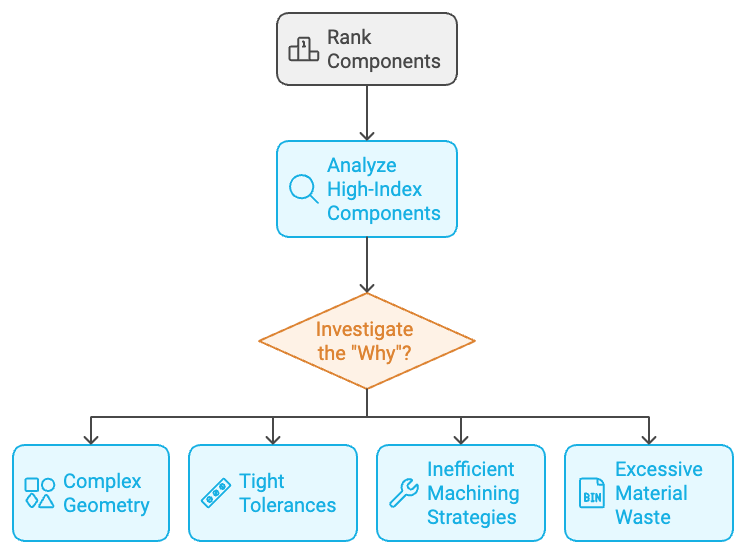

2. Prioritization and Analysis:

- Rank Components: Create a list of components ranked in descending order of their “Idiot Index” values. This highlights the parts with the greatest potential for cost reduction.

- Analyze High-Index Components: Focus your attention on the components with the highest “Idiot Index” scores. These are the prime candidates for optimization.

- Investigate the “Why”: Delve deeper into the factors contributing to the high index. Is it due to complex geometry, tight tolerances, inefficient machining strategies, or excessive material waste?

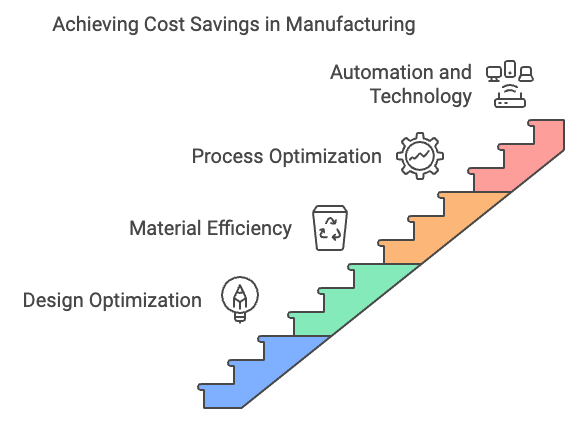

3. Implementing Cost-Saving Measures:

- Design Optimization: Collaborate with design engineers to simplify complex features, relax tolerances where possible, and optimize designs for manufacturability.

- Material Efficiency: Explore near-net-shape manufacturing techniques to reduce material waste. Consider alternative materials that offer a better cost-to-performance ratio.

- Process Optimization: Analyze machining parameters, toolpaths, and setups to identify areas for improvement. Investigate alternative machining strategies and tooling options that can reduce cycle times and improve efficiency.

- Automation and Technology: Explore automation opportunities to reduce manual labor and improve consistency. Investigate advanced CNC machining technologies that offer higher speeds, feeds, and precision.

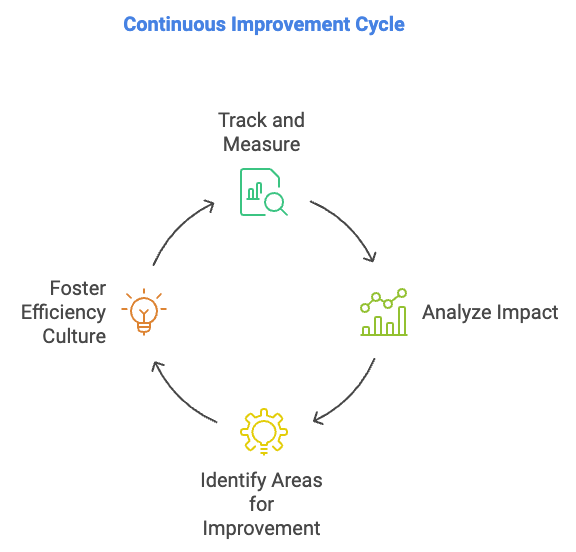

4. Continuous Improvement:

- Track and Measure: Regularly monitor the “Idiot Index” for your components. Track the impact of implemented changes and identify areas for further improvement.

- Foster a Culture of Efficiency: Encourage a mindset of continuous improvement and cost-consciousness throughout your organization. Empower employees to identify and suggest cost-saving measures.

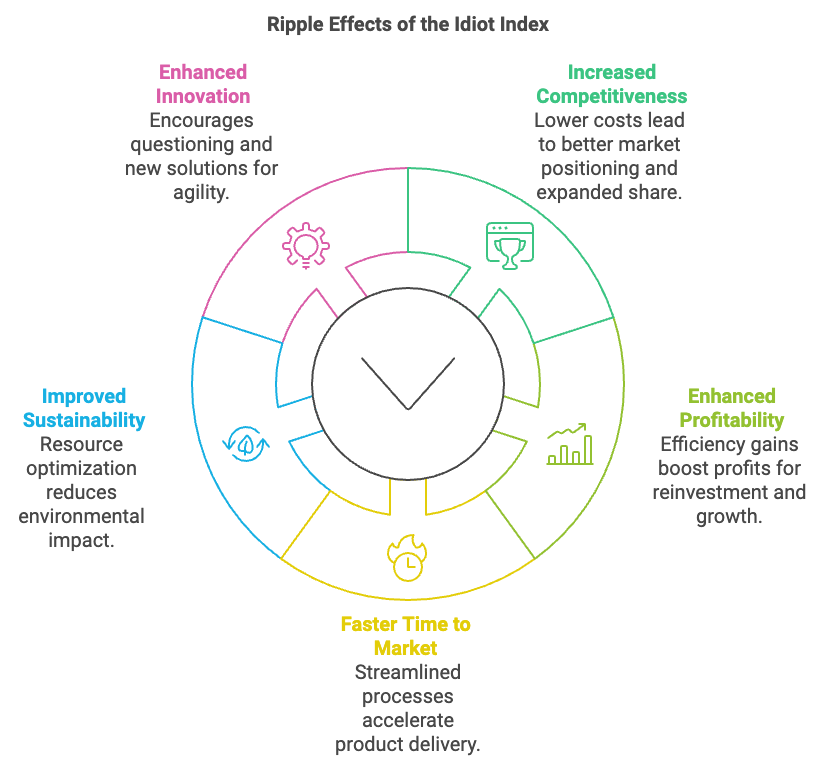

Beyond Cost Savings: The Ripple Effect of the “Idiot Index”

While the primary focus of the “Idiot Index” is cost reduction, its benefits extend far beyond the bottom line. Implementing this metric can have a positive ripple effect throughout your CNC machining operations:

- Increased Competitiveness: Lower production costs translate to more competitive pricing, allowing you to win more business and expand your market share.

- Enhanced Profitability: Improved efficiency and reduced waste directly impact profitability, allowing you to reinvest in your business, upgrade equipment, and attract top talent.

- Faster Time to Market: Streamlined designs and optimized processes lead to shorter lead times, enabling you to get your products to market faster and seize opportunities.

- Improved Sustainability: Reducing material waste and optimizing resource utilization aligns with sustainability goals, minimizing your environmental impact.

- Enhanced Innovation: The “Idiot Index” fosters a culture of questioning assumptions and exploring new possibilities, leading to innovative solutions and a more agile and responsive organization.

Conclusion: Embracing the “Idiot Index” for a Leaner, More Efficient Future

Elon Musk’s “Idiot Index” is not about assigning blame or pointing fingers. It’s a powerful tool for self-reflection, continuous improvement, and unlocking hidden potential within your CNC machining operations. By embracing this simple yet effective metric, you can transform your approach to manufacturing, driving efficiency, reducing costs, and gaining a significant competitive edge in today’s demanding market.